How Air Compressors Work: A Complete Guide

Air compressors play a relatively new role in major workshop systems, taking the place of heavy-duty belts and shafts that were used to route power to various pieces of machinery.

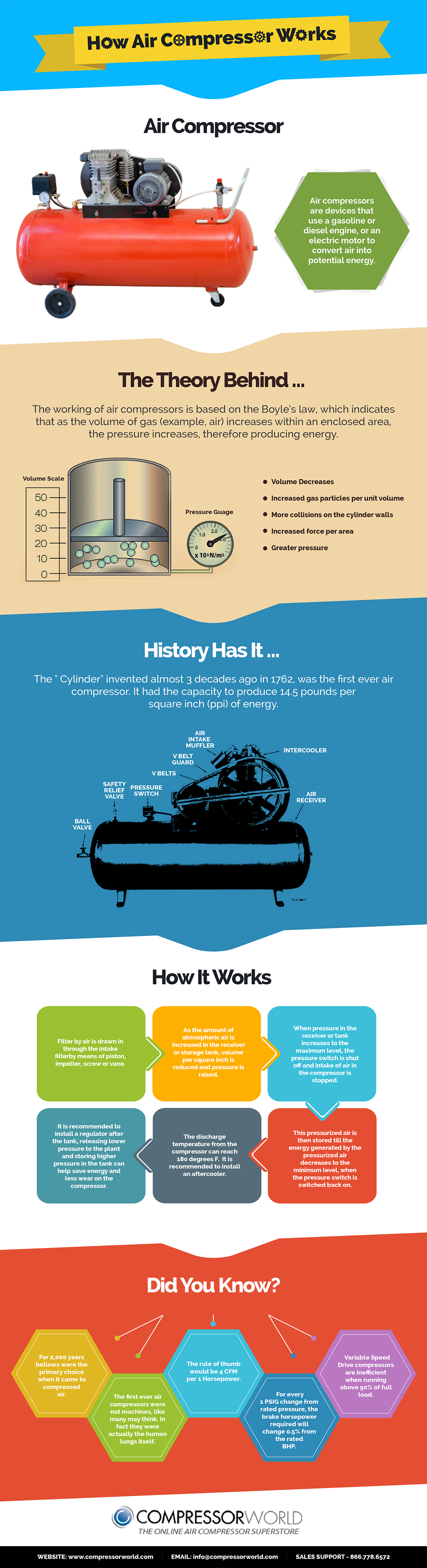

The underlying physics have not changed — a certain volume of gas increases within an enclosure, causing an increase in pressure and thereby producing an output of power. While this remains true, modern air compressors are more compact and efficient, making them suitable for a much wider range of applications.

But what exactly makes them function? Let's take a closer look.

The basics of air compressors

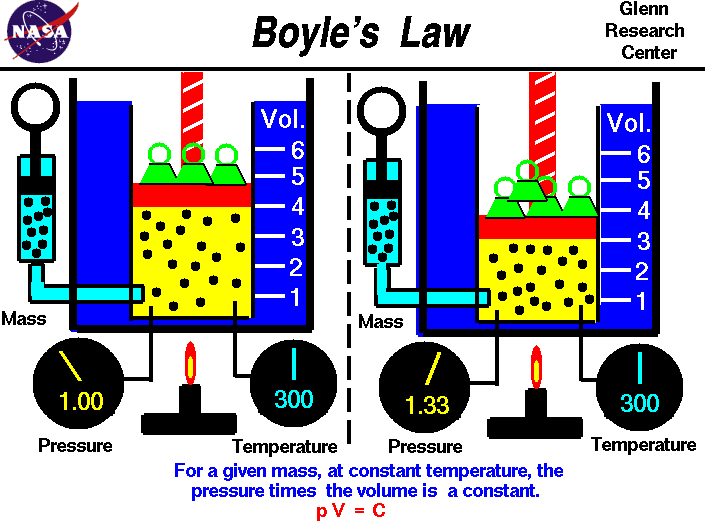

If you're new to the world of air compressors, knowing how they work can be advantageous knowledge that comes with a sizeable learning curve. The best first step is understanding Boyle's Law, which is the main underlying mechanism. It states that when the temperature of gas is constant, its volume and pressure are inversely proportional.

The equation derived from Boyle's Law is pV=C

Therefore, with temperature being constant, the volume decreases as pressure increases and vice versa. The following graphic, provided by the National Aeronautics and Space Administration (NASA) should provide added clarity.

Components of an air compressor

An air compressor is generally comprised of four basic components:

- Electric motor - powers the compressor pump by driving a pulley and two belts. The power is transfered via a crankshaft and flywheel.

- Compressor pump - compresses incoming air, then discharges it into a receiver

- Receiver tank - stores compressed air

- Pressure switch - shuts down the motor when compressed air reaches the receiver tank's factory-set limit

While these are the primary components, air compressors also require installing additional components to achieve effective and efficient operation. Those additional components include:

- Air dryers, after-coolers - cools the hot compressed air and prevents the system from overheating

- Air filtration, moisture removal pipelines - installed to drain out the condensed moisture from the compressor before it reaches a tool

- Air lubricator - used in tools that require lubrication

- Pressure gauge - measures and regulates the air pressure to tools

- Shut-off valves - installed in each drop line to isolate accessories from the air compressor for maintenance

The inner workings of an air compressor

The function of an air compressor is quite simple, once you understand all of its main components. More and more air is drawn into the compressor, causing its pressure to increase as a higher volume is forced into a limited space.

When a tank's designated pressure is reached, the compressor shuts off and stores that compressed air until it's released by a user or system for various applications. This air can be used across a wide variety of domestic and industrial tools or machines. It's impressive to watch as a compact device, based on a simple mechanism, can offer so much power.

Have any lingering questions? Reach out to one of our experienced air compressor experts by calling 866-778-6572 or sending an email to info@compressorworld.com